Core Advantages of Moisture-proof PE Block Bottom Valve Bag

The anti-static performance is outstanding, ensuring safety. Anti-static masterbatches (such as carbon-based conductive materials and permanent antistatic agents) are added to the bag material. The surface resistance is controlled between 10⁶-10¹¹Ω, which can quickly conduct away the static electricity generated by friction. This avoids dust explosions caused by static electricity accumulation, making it suitable for flammable and explosive powder materials like chemical raw materials and electronic powders.

The valve and seams are treated with anti-static processes, such as sewing with conductive fibers and using anti-static heat-sealing adhesives. This ensures that the overall static dissipation path is unobstructed, complying with standards like General Specification for Anti-Static Packaging Materials (GB/T 23316).

The sealing and moisture resistance are excellent. The PE material itself has waterproof and barrier properties. Combined with the heat-sealing or bonding process of the square-bottom valve, a fully enclosed space is formed. This prevents materials from getting damp, oxidized, or contaminated, which is crucial for environment-sensitive materials such as lithium battery positive and negative electrode materials and precision electronic powders.

The valve design supports air pressure sealing during automatic filling. When unloading, dust-free operation can be achieved through the bottom opening or valve removal, reducing dust leakage.

The structure is stable, with strong load-bearing capacity and durability. The square-bottom structure allows empty bags to stand stably. After filling, they form a cube, which is easy to stack (the stacking height can reach 3-5 layers), saving warehouse space. The multi-layer composite structure (such as PE + anti-static woven cloth) can carry 25-50kg of materials, and its tear resistance is more than 30% higher than that of ordinary PE bags.

The anti-static performance is long-lasting. Even after multiple foldings and frictions, the surface resistance can remain stable, making it suitable for repeated use or long-term storage.

It is compatible with automated production, improving efficiency. The valve specifications are compatible with mainstream filling machines (valve inner diameter 50-100mm), supporting high-speed quantitative filling (filling speed can reach 500-1000 bags per hour). This reduces manual contact and lowers the risk of static electricity. Empty bags are small in volume when folded, reducing transportation costs.

It combines environmental protection and versatility. The PE material is recyclable, and some products add degradable components, meeting environmental protection requirements. In addition to anti-static properties, functions such as UV resistance and puncture resistance can be added as needed (for example, adding metallocene-modified PE to improve weather resistance), adapting to outdoor storage or complex transportation environments.

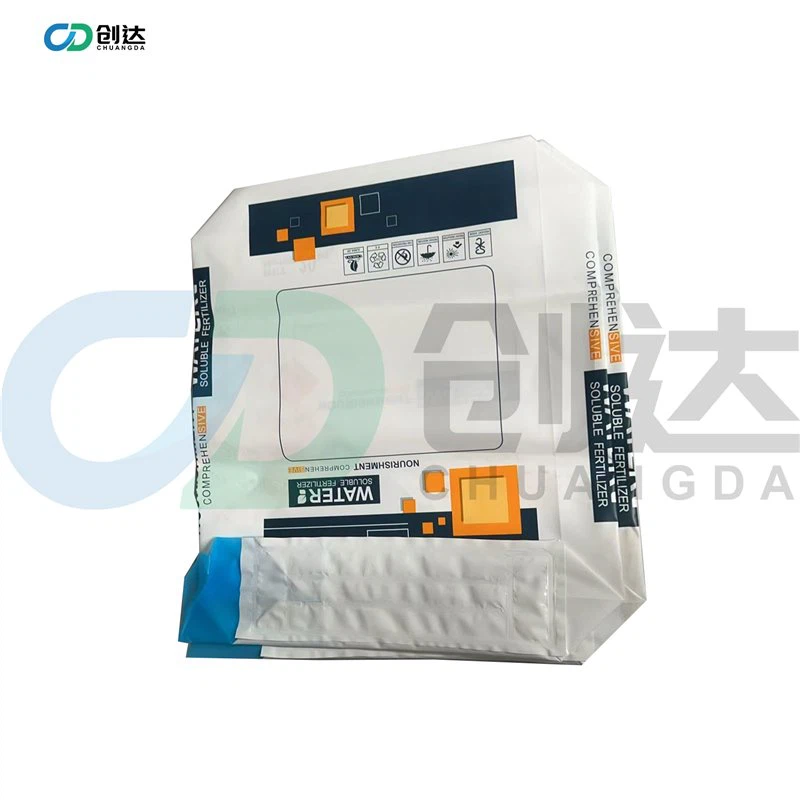

Common Sizes of Moisture-proof PE Block Bottom Valve Bag

Sizes are usually customized according to material density, filling equipment, and load-bearing requirements. Here are typical specifications.

Small anti-static bags have dimensions of 350×250×500mm, with a load-bearing capacity of 10-15kg, suitable for laboratories and small-batch packaging of electronic components.

Standard industrial bags measure 480×320×750mm, bearing 25-30kg, used for bulk transportation of chemical raw materials and lithium battery materials.

Large anti-static bags are 600×400×900mm in size, with a load-bearing capacity of 40-50kg, applicable to warehousing and wholesale of powder coatings and plastic particles.

Special customized parameters include valve details: anti-static valves can be designed as single-opening or double-opening, with diameters adjusted according to the filling machine interface (common ones are 60mm and 80mm).

The thickness of the bag body: the thickness of anti-static PE film is usually 80-120μm. To enhance puncture resistance, anti-static woven cloth of 200-300g/m² can be compounded.

Application Scenarios and Selection Suggestions

Applicable materials include lithium battery positive and negative electrode materials, electronic-grade silicon powder, flammable chemical powders, precision ceramic powders and other materials sensitive to static electricity.

Key points for selection: Confirm the electrostatic sensitivity level of the material and select bags with corresponding surface resistance (for example, semiconductor materials require surface resistance ≤10⁹Ω).

If Moisture-proof PE block bottom valve bag involves dangerous goods transportation, it must comply with Dangerous Goods Transport Packaging Specifications (such as UN certification), and print anti-static signs (⚡) and warning words on the bag.

If you need to customize special sizes or functions (such as food-grade anti-static, anti-strong acid corrosion), it is recommended to contact the supplier to provide material testing reports and anti-static performance test data (such as friction voltage decay time).

Easy to stack: After filling with materials, it is cubic, with a regular shape, so the stacks are neat and beautiful. Moreover, the stacking height can be greatly increased, saving storage space. Moisture-proof PE block bottom valve bag is very suitable for scenarios that require a large amount of storage and transportation of carbon black, and also convenient for loading, unloading and handling.

Convenient filling: It is suitable for automatic filling equipment. The valve at the top or bottom of the packaging bag can be inserted into the material filling port of the valve bag filling machine for high-speed quantitative filling. The filling speed is fast and efficient, and it can also reduce the dust scattering during filling, improving the working environment.

Good environmental performance: PE material can be recycled, and some products can also add degradable materials, meeting environmental protection requirements. In addition, some bags are made of environmentally friendly glue and other materials, which are friendly to the environment.

Size 14: Bag width is usually between 35-60cm. Bag length is generally 45-110cm. Bottom width is commonly 8-18cm. Load-bearing capacity: It can bear 0.5-25kg, up to 50kg. Common specifications include bags that can hold 25kg of carbon black, with sizes such as 50×80cm and 55×90cm. Specific sizes can be customized according to customer needs.

Hot Tags: moisture-proof pe block bottom valve bag, China moisture-proof pe block bottom valve bag manufacturers, factory, Food Grade PE Square Valve Bag, Heat sealed PE Square Valve Bag, Moisture proof PE Block Bottom Valve Bag, PE Square Valve Bags for Agricultural Products, Polyacrylamide PE Square Bottom Valve Bag, Rubber Additives PE Square Bottom Valve Bag